INJECTION MOULDING AUSTRALIA

Case Studies

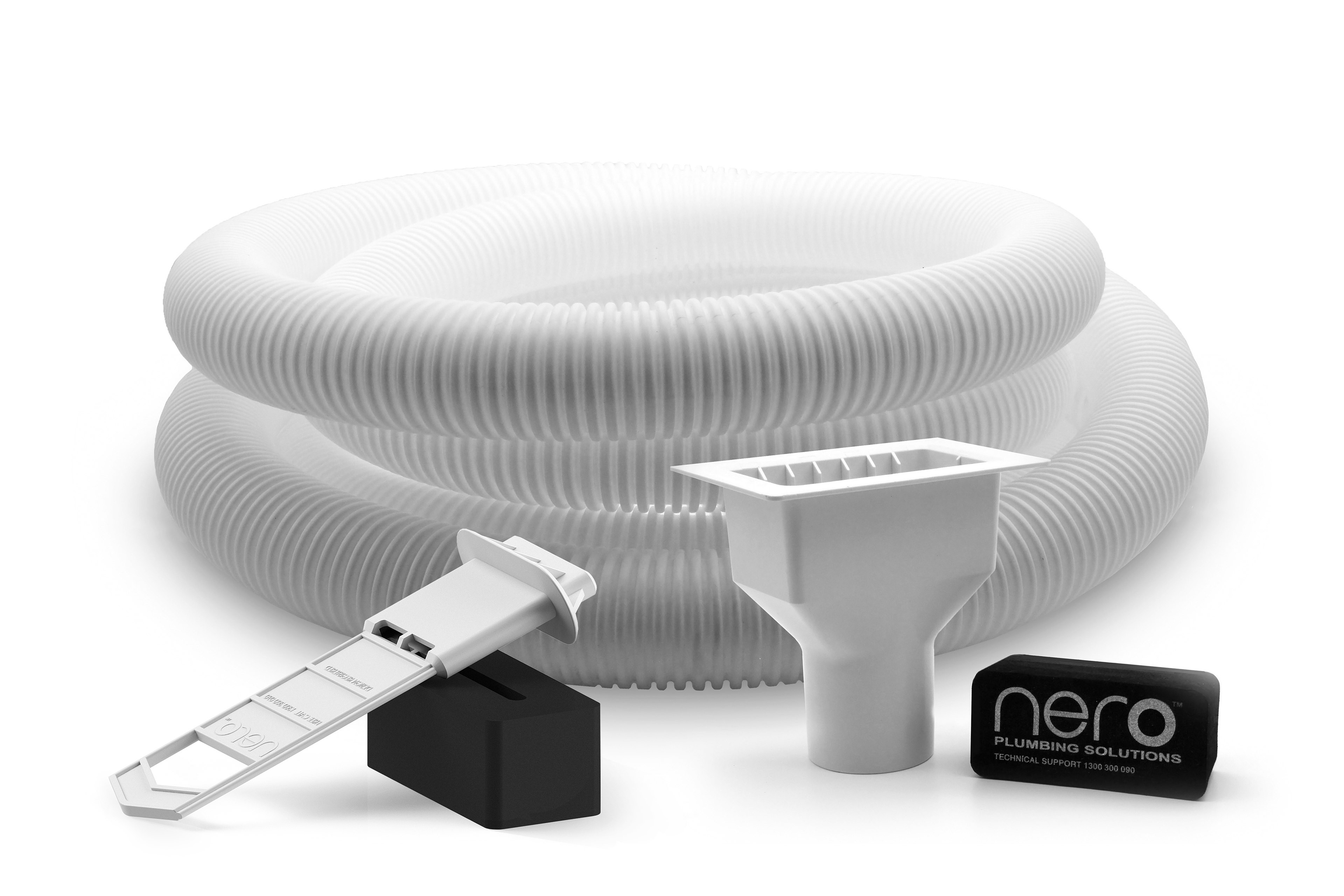

Temporary Down pipes

Injection Moulding Australia was approached by a building company who were having issues with drainage off the roof during construction. Water was often left sitting next to the slab which was causing structural issues. The problem was that their current drainage method was not strong enough to withstand significant downpours and high winds. Injection Moulding Australia were able to work closely with the building company to identify the current issues and come up with a solution that was not only practical and effective, but environmentally friendly. Injection Moulding Australia designed and prototyped a number of different solutions until the perfect resolution was found. The temporary down pipe connects to the gutters before downpipes are installed and guides all water from the roof away from the slab ensuring its structural integrity. The Temporary Down Pipe can also be taken down and re-used on another site, instead of the old method which could only be used once before being thrown away.

Air Vent

Injection Moulding Australia was contacted by a building company who needed an air vent designed that could seamlessly be installed in both the eaves and brickwork without drawing attention to it. The Air vent also needed to comply with the Australian Standards, Construction of buildings in bushfire-prone areas (AS3959-2009.) It was found that during a bushfire embers were getting into air vents and causing further spread of fire. Injection Moulding Australia were able to come up with a 100% recyclable, easy to install solution using a two-part snap lock fit design. The air vent, made from a fire rated ABS, also integrated a fire rated stainless steel woven mesh which meets and exceeds the building requirements of AS3959-2009. The mesh sits inside the air vent and is removable and replaceable, it stops any embers from entering the air vents and causing further fire spread. Working closely with the building company Injection Moulding Australia designed, prototyped, tooled and produced the air vent for the builder. It was also made available in a variety of colours to suit any application.

Design &

Modelling

3D Printing

& Prototyping

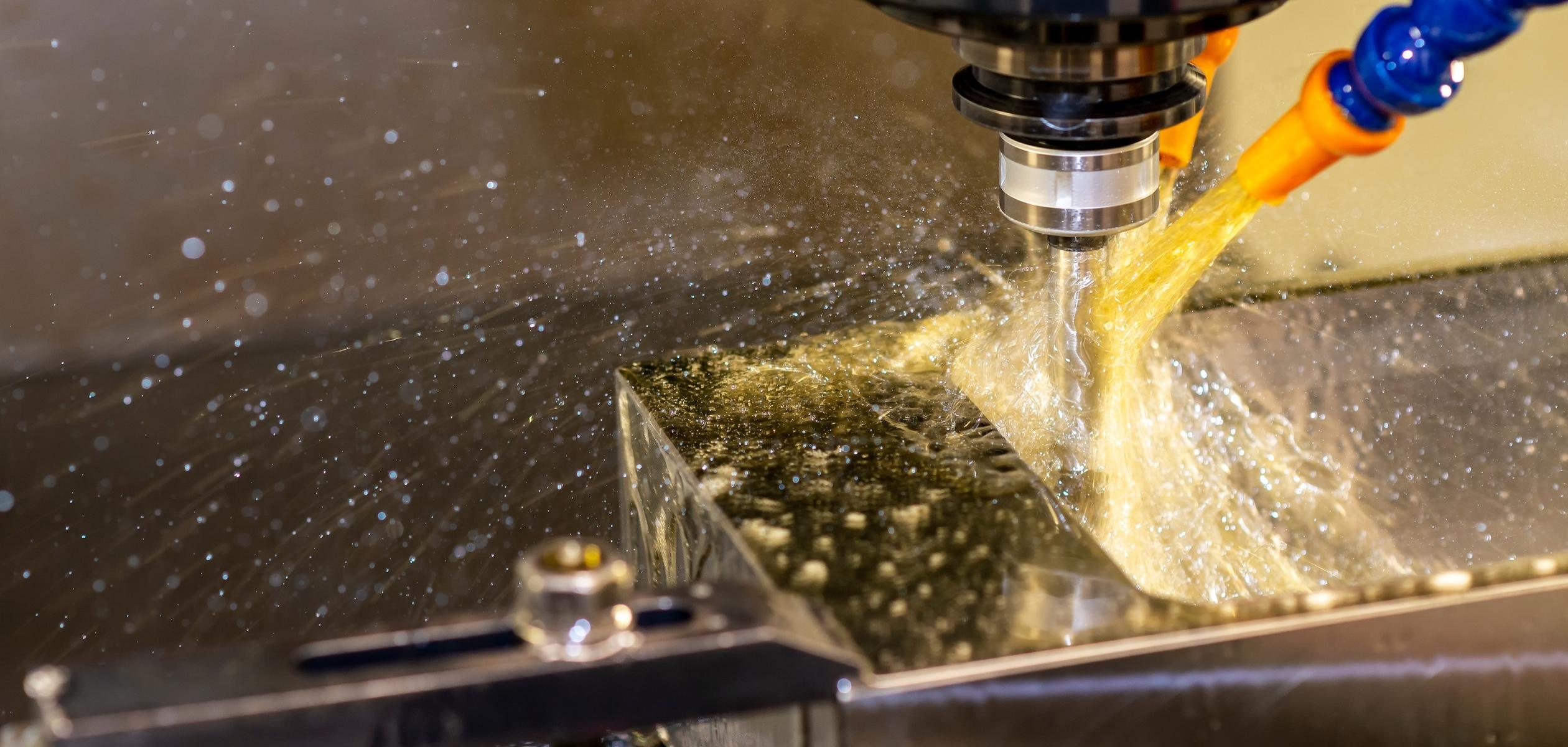

Injection

Moulding

Tools/Mould

Development

Packaging

.

Get in touch with our specialists

Click on the button below to be redirected to our contact us page and get in touch with an Injection Moulding specialist.